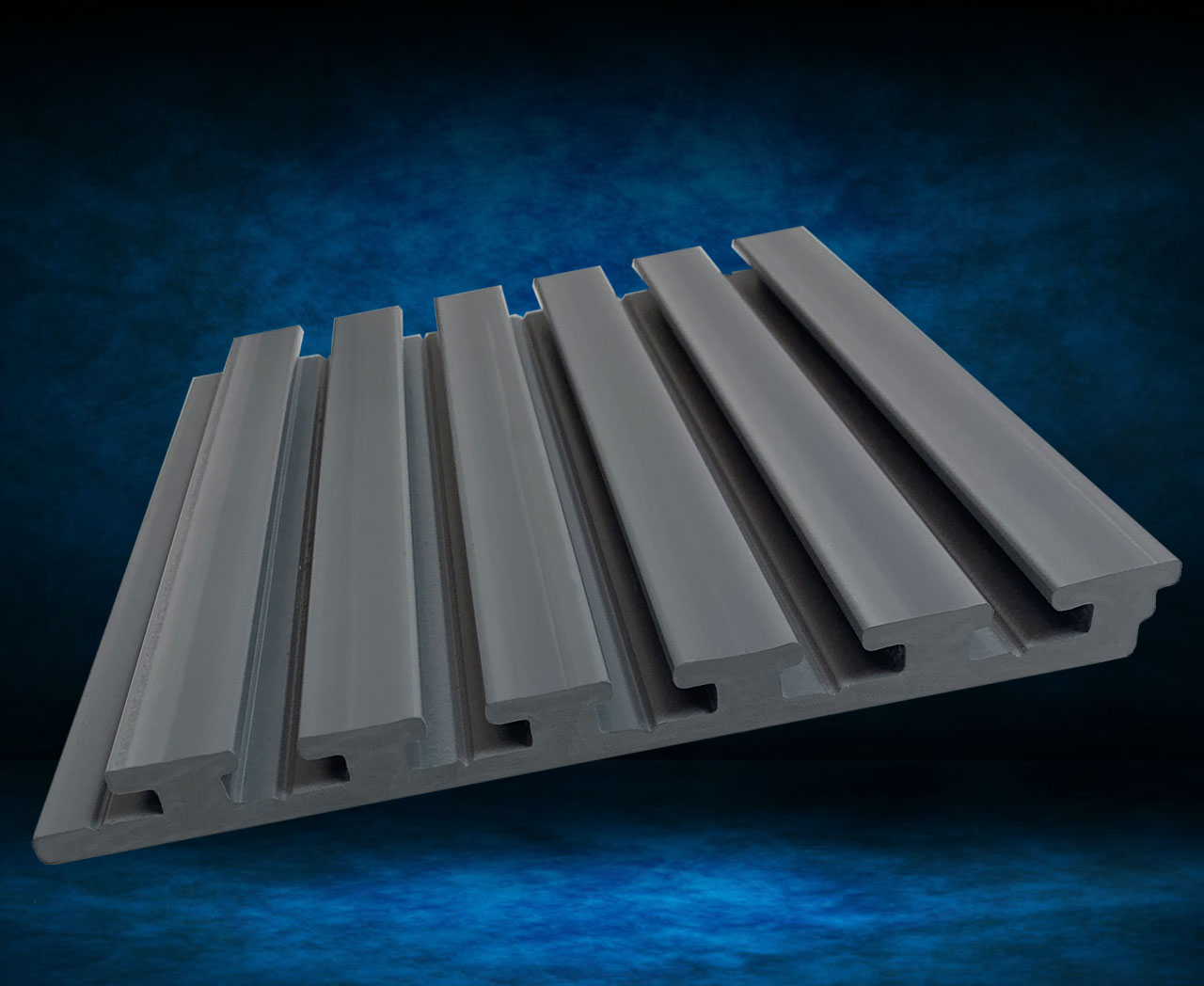

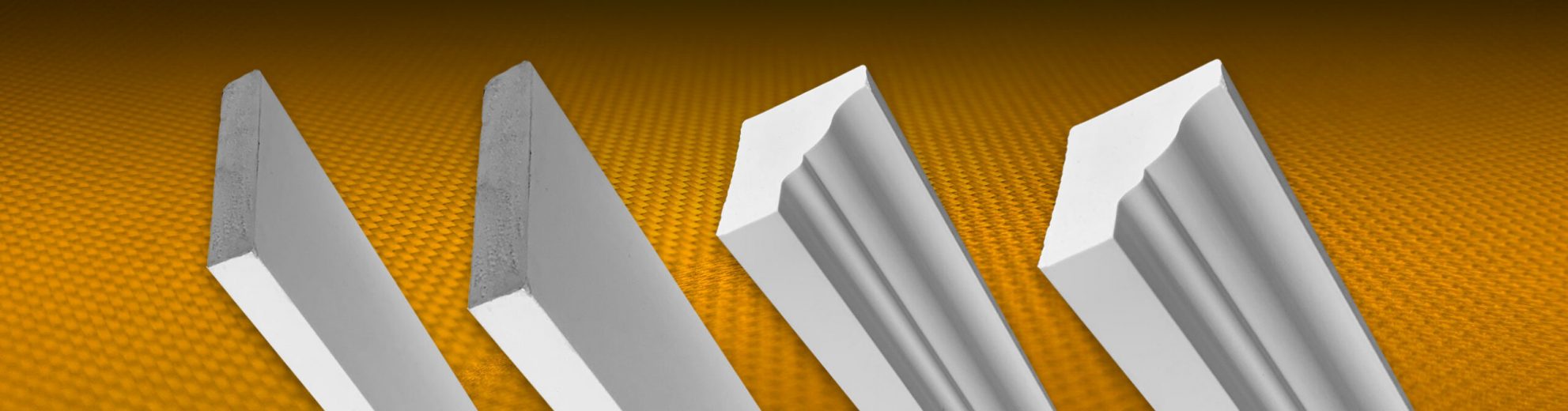

PVC is a very versatile plastic material and is a great material to foam. Rigid PVC in its non-foamed state is one of the most economical, rigid, unreinforced thermoplastic materials commercially available. Barbour Plastics strongest, highest impact, exterior grade compound has a specific gravity greater than 1.40. We have the ability through varied foaming techniques to reduce the weight and control the specific gravity anywhere between a 0.35 and 1.20 density. If you have thick profiles and need weight or cost reduction or require a material with good thermal insulation values, then foamed PVC should be considered.

PVC Foamed Extrusions are a great choice for applications that require:

GOOD INSULATION PROPERTIES

LIGHT WEIGHT MATERIAL

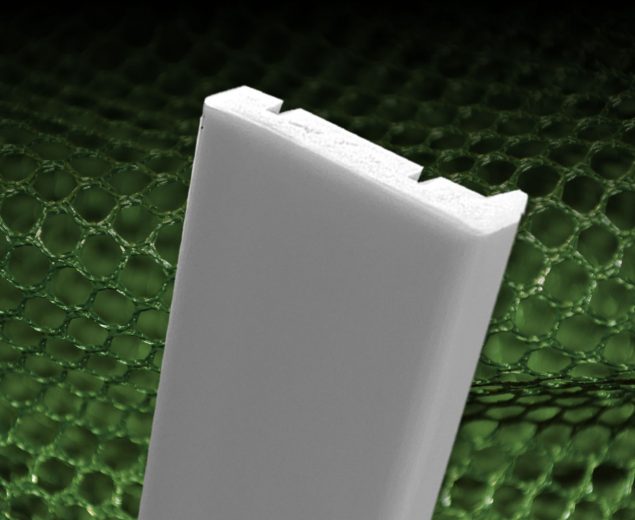

FREE FOAM ADVANTAGES

CELUKA FOAM ADVANTAGES

MENU