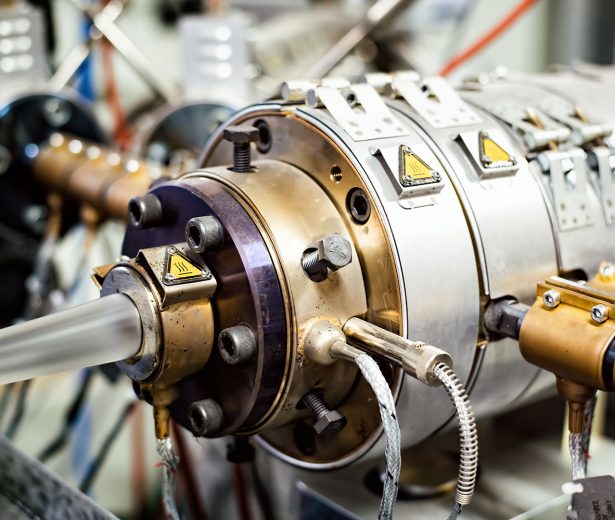

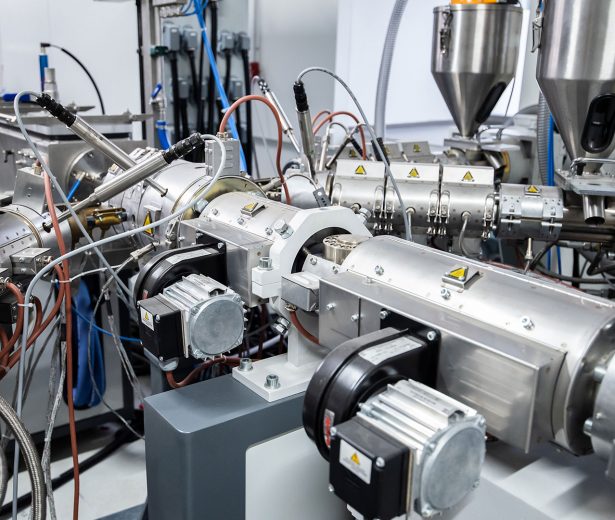

Plastic extrusion is the most economical and efficient way to manufacture long linear profiles. There are many strategies to achieving your product design within your time frame, tooling budget and unit target cost. In most cases you can extrude plastic as fast as you can efficiently control the cooling process. The faster you convert raw material into a finished extrusion, the more sophisticated and elaborate the tooling is required. Barbour Plastics has earned an excellent reputation as a plastic profile extrusion facility by listening to their customers needs. At Barbour Plastics, we design extrusion tooling to meet our customers requirements. If quick delivery, low tooling cost, and lower volume of parts then we can design simpler, lower throughput tooling that will meet your needs. If lowest part cost for high volume production then we can design high volume tooling that can be achieved by utilizing a larger extruder or designing multi strand tooling for maximum throughput. Call us today and ask to speak to one of our experienced technical sales team members.

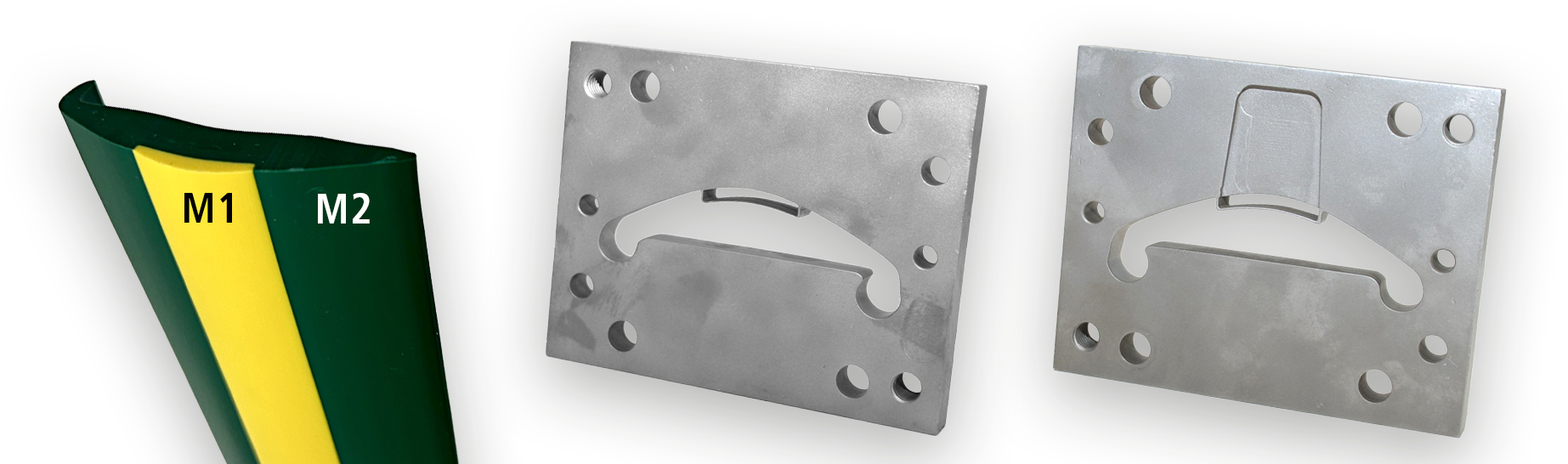

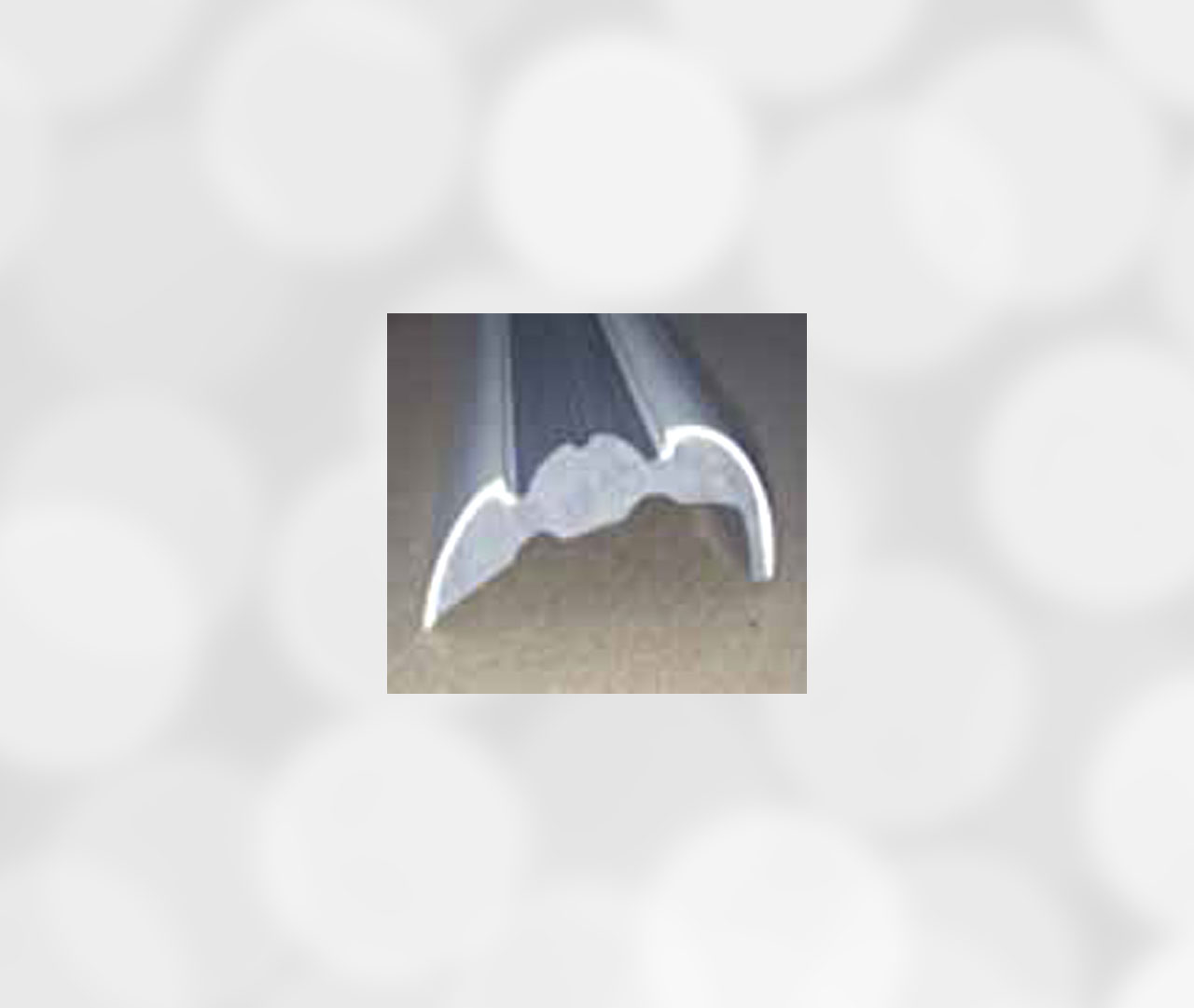

Two materials are simultaneously extruded to create one bonded product. Adding a third material to an extrusion is sometimes required to make parts fully functional in their operational setting. Tri-extruded products can often open the door to use a versatile plastic part meeting multiple requirements rather than using multiple materials to complete the same function. Trust the years of experience in completing the Tri-extrusion products at Barbour Plastics Inc.

MENU