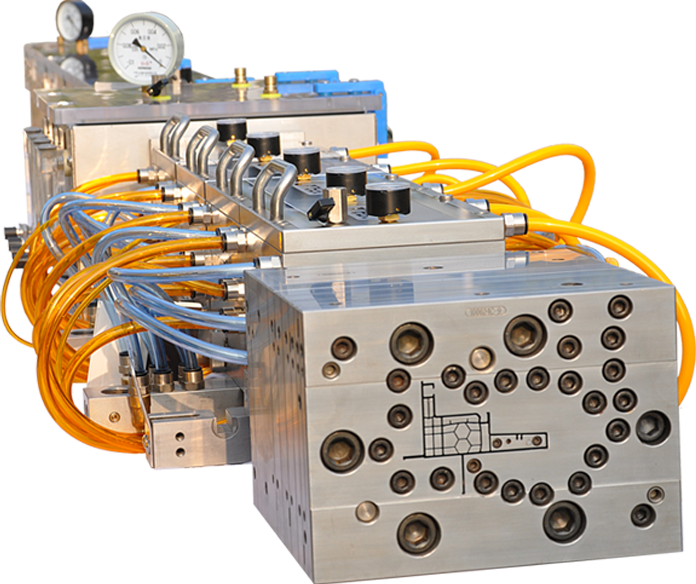

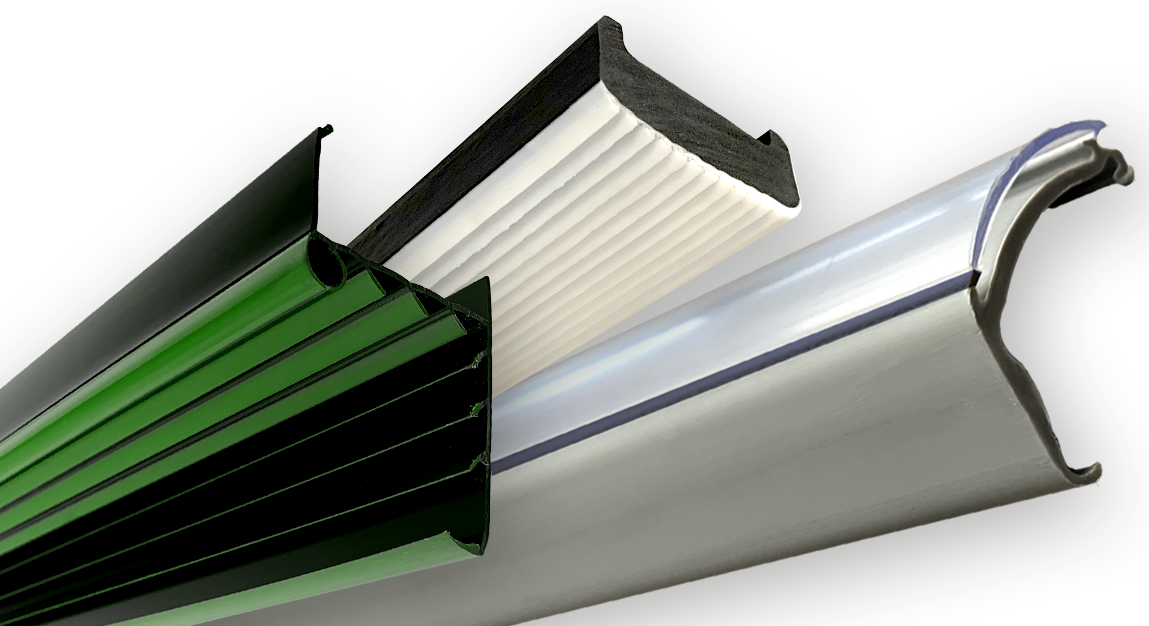

Barbour Plastics has been honing its manufacturing of quality plastic extrusions for over 40 years. Our fully capable engineering team utilizes custom CAD software to design in-house tooling specific to our customer’s needs. Having the design, manufacturing, and extrusion process all under one entity allows our company to remain priced competitively, quick on product turnaround, and seamless in maintenance on long term partnerships. Barbour Plastics’ 28 extrusion lines make for a key nationally competitive manufacturer for all American OEMs to consider.